- View Mobile Number

| Business Type | Manufacturer, Exporter, Supplier |

| MeteorCNC:4F Series Catalog | |

| MeteorCNC:4F Series DataSheet | |

| After-Sales Service Provided | Yes |

| Click to view more | |

Product Details

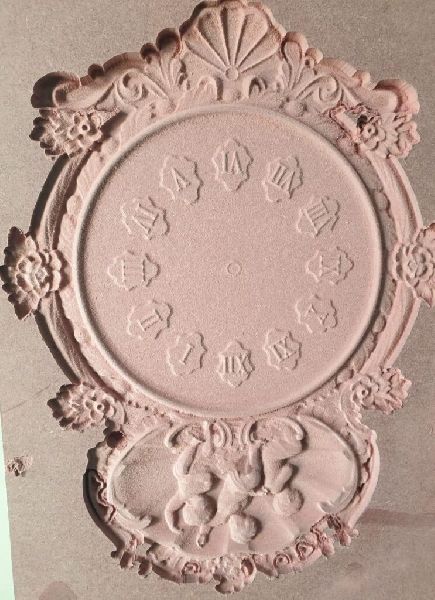

MeteorCNC 4F: Upto 4 axes CNC controller running with PC / Laptop based Software user interface running with high speed differential pulse & direction output for smooth operation. It is using 2D DXF or Plt files. FloydCNC converts this .dxf or .plt file to GCode internally & it will run the machine accordingly.

MeteorCNC 4F is a 4-axis CNC controller operated with pc based user interface called “Floyd” software. 4F series controller comes with 4 axis individual jitter free differential pulse and direction, 24 digital NPN inputs, 12 digital NPN outputs, 0-10v analog output for the spindle, high speed external encoder input and software license.

“Floyd” software can be installed in any windows 7 or windows 10 computer or Laptop with minimum specifications of the PC like 2Gb/4Gb RAM, 32GB SSD or HDD inbuilt graphics care also sufficient to run the software with 3D display. Software running inside computer communicates with control card over the lan cable. User interface has facility for inbuilt CAM generation using 2D .dxf or .plt files. Auto Centering facility provides additional ease to user to setup the job and finding the center in both X and Y direction using graphical interface. 3D view provides wire mesh interpretation of the toolpath where user can zoom in, zoom out, rotate, pan etc to view job going to go for cutting or engraving. However, as the name indicates, 4-axis machining adds an axis of rotation to the standard X, Y, and Z movement. This extra movement is rotation

along the X-axis or Y axis, which forms a fourth plane. The rotation may be accomplished by moving the tool or the workpiece which is being machined, and the axis of rotation may be parallel to or perpendicular to the tool surface.

Software also provides machine boundaries for ease of user operation and ware the user if any movement is going to violate the machine boundaries prior to the job start which helps user for unnecessary damage in tool or workpiece and saving lots of user time making him productive in the work.

Best suitable for die and mold making machine, laser machines, plasma cutting machine, multi side wood drilling and slot application etc.

Additional Information:

- Item Code: MeteorCNC

- Delivery Time: 1 day