- View Mobile Number

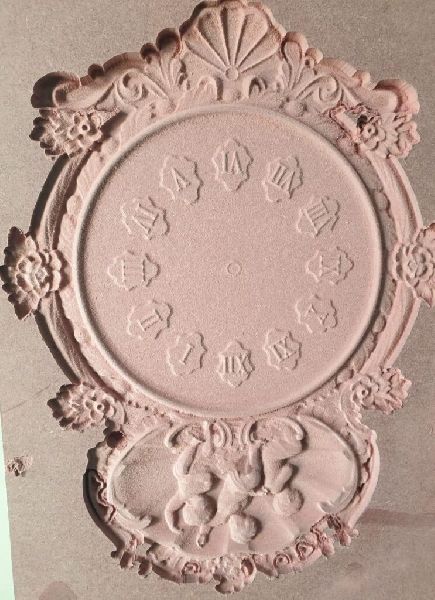

CNC Router Controller

Leading Manufacturers, Exporters and Wholesaler of Meteor CNC 4F Series 4 Axes CNC Controller, MeteorCNC 3H Series 3 Axis CNC DSP Controller, MeteorCNC 4H Series 4 Axes CNC Router Controller and MeteorCNC 4T Series, wood lathe controller from Mumbai.

| Business Type | Manufacturer, Exporter, Supplier |

| MeteorCNC:4F Series Catalog | |

| MeteorCNC:4F Series DataSheet | |

| After-Sales Service Provided | Yes |

| Brand Name | Accelus Robotics |

| Warranty | 1year |

| Power Source | Electric |

| Condition | New |

| Voltage | 220V, 24Vdc |

| Feature | Durable, Stable Performance |

| Shape | Rectangular, Pc Based |

| Type | Cnc Controller |

| Country of Origin | India |

| No. Of Axis | 4 |

| Axis Name | X, Y, Z, 4th |

| Number of Inputs | 24 |

| Types of Inputs | Isolated NPN or PNP |

| No. Of Outputs | 12 |

| Types of Outputs | Isolated PNP |

| Encoder | Differential Encoder Facility for remote MPG |

| Spindle Operation | 0-10V Analog Output |

| Hand-handle | Graphics LCD with 22 Keys |

| Product Code | MeteorCNC 4F |

| Port | Mumbai India |

| Payment Terms | T/T |

| Delivery Time | 1-2 Days |

MeteorCNC 4F: Upto 4 axes CNC controller running with PC / Laptop based Software user interface running with high speed differential pulse & direction output for smooth operation. It is using 2D DXF or Plt files. FloydCNC converts this .dxf or .plt file to GCode internally & it will run the machine accordingly.

MeteorCNC 4F is a 4-axis CNC controller operated with pc based user interface called “Floyd” software. 4F series controller comes with 4 axis individual jitter free differential pulse and direction, 24 digital NPN inputs, 12 digital NPN outputs, 0-10v analog output for the spindle, high speed external encoder input and software license.

“Floyd” software can be installed in any windows 7 or windows 10 computer or Laptop with minimum specifications of the PC like 2Gb/4Gb RAM, 32GB SSD or HDD inbuilt graphics care also sufficient to run the software with 3D display. Software running inside computer communicates with control card over the lan cable. User interface has facility for inbuilt CAM generation using 2D .dxf or .plt files. Auto Centering facility provides additional ease to user to setup the job and finding the center in both X and Y direction using graphical interface. 3D view provides wire mesh interpretation of the toolpath where user can zoom in, zoom out, rotate, pan etc to view job going to go for cutting or engraving. However, as the name indicates, 4-axis machining adds an axis of rotation to the standard X, Y, and Z movement. This extra movement is rotation

along the X-axis or Y axis, which forms a fourth plane. The rotation may be accomplished by moving the tool or the workpiece which is being machined, and the axis of rotation may be parallel to or perpendicular to the tool surface.

Software also provides machine boundaries for ease of user operation and ware the user if any movement is going to violate the machine boundaries prior to the job start which helps user for unnecessary damage in tool or workpiece and saving lots of user time making him productive in the work.

Best suitable for die and mold making machine, laser machines, plasma cutting machine, multi side wood drilling and slot application etc.

Additional Information:

- Item Code: MeteorCNC

- Delivery Time: 1 day

| Business Type | Manufacturer, Exporter, Supplier |

| MeteorCNC:3H Series Catalog | |

| MeteorCNC:3H Series DataSheet | |

| After-Sales Service Provided | Yes |

| Brand Name | Accelus Robotics |

| Warranty | 1year |

| Power Source | Electric |

| Condition | New |

| Voltage | 24Vdc |

| Feature | Stable Performance |

| Shape | Rectangular |

| Type | Cnc Controller |

| Country of Origin | India |

| No .of Axis | 3 |

| Number of Inputs | 15 (Isolated NPN) |

| No. of Outputs | 8 (Isolated NPN) |

| Spindle | 0-10V Analog Output/Multi speed |

| Storage capicity | Upto 1GB |

| Product Code | MeteorCNC 3M/3H |

| Port | Mumbia India |

| Payment Terms | T/T |

| Delivery Time | 1-2 Days |

MeteorCNC 3H series is 3 axis CNC DSP Controller Manufacturer with handhandle running upto 500khz differential pulse & direction output for smooth operation with 15 Inputs,8 Outputs & 1 Analog output.

MeteorCNC 3M is 3 axis CNC controller comes with control card and operated with handheld with 128×64 graphics LCD, Easy to learn and user-friendly UI comes with blue and white color combination which gives an appealing look to the user.

Easy to setup and configure any 3 axis CNC machine with inbuilt MPG that provides ease of operation for job setup. Setting backup option also available using pen drive and network connectivity facility for remote debugging and program transfer facility using lan cable with and option for handheld cables length upto 50 Mtrs as per user requirements.

The 3M series Controller provides at up to 500 kHz jitter free differential pulse and direction output, making it ideal for smooth motion at the motor end and precision work. When the job at hand doesn’t call for a lot of depth or detail, a machine with only three axes will do just fine. That’s why it’s one of the most popular methods for making mechanical components for robotics and other forms of automation and specially for wood working market and interior industries.

You may also use it for boring, milling slots, tapping, and drilling holes in addition to cutting sharp edges.

Features

- The file can be transferred by using USB as well as over the network.

- Position of axis & line number will be store on power off.

- Providing a total of 9 work co-ordinate systems.

- Supporting ISO Standards rs274d G codes & M codes.

- Velocity & Acceleration management for each axis & overall path basis.

- Inbuilt MPG is available on handhandle.

Applications

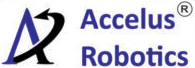

- Metal Engraving

- Wood Carving.

- Stone cutting.

- Die making.

| Business Type | Manufacturer, Exporter, Supplier |

| MeteorCNC:4H Series Catalog | |

| MeteorCNC:4H Series DataSheet | |

| After-Sales Service Provided | Yes |

| Brand Name | Accelus Robotics |

| Warranty | 1year |

| Power Source | Electric |

| Condition | New |

| Voltage | 24Vdc |

| Feature | Durable, Stable Performance |

| Certification | CE Certified |

| Shape | Rectangular |

| Type | Cnc Controller |

| Country of Origin | India |

| No. of axis | 4 |

| Axis Name | X, Y, Z, 4Th |

| Spindle Operation | 1-10V Analog output or NPN multistep |

| Storage Capicity | Upto 1GB |

| Product Code | MeteorCNC 4H |

| Port | Mumbai India |

| Payment Terms | T/T |

| Delivery Time | 1-2 days |

MeteorCNC 4H Series 4 Axes CNC Router Controller

MeteorCNC 4H series is 4 axes DSP router controller manufacturer with handheld running upto 500khz differential pulse & direction output for smooth operation with 24 Inputs, 12 Outputs, 1 Analog output and encoder facility available.

MeteorCNC 4H series is a 4 axes DSP router controller operated with handheld provides up to 500khz jitter free differential pulse & direction output for smooth motion at the motor end. It comes with 4 axis control card and handheld and inbuilt MPG available with few extra inputs and outputs with additional facility of external high speed differential encoder input which can be used for either MPG remote for jogging of axis OR spindle encoder feedback for tapping cycle.

A 4-axes CNC machine functions much like its 3-axes counterpart. With addition of one extra rotational motion from the controller makes it very special for making critical works. The workpiece is in a stationary position, and the cutting tool works on it to remove material and mold the desired part. However, as the name indicates, 4-axis machining adds an axis of rotation to the standard X, Y, and Z movement. This extra movement is rotation along the X-axis, which forms a fourth plane the A-axis OR rotational along Y-axis.

The rotation may be accomplished by moving the tool or the workpiece which is being machined, and the axis of rotation may be parallel to or perpendicular to the tool surface. The orientation of the axis of rotation determines how easy it is to machine certain features and undercuts on a given machine.

4 individual simultaneously running axis machine is majorly used in wood working / router machine industries for making statues, stone cutting/ engraving machine for pillar making etc. making the job faster and easier for the users.

Additional Information:

- Delivery Time: Within a Day

| Business Type | Manufacturer, Exporter, Supplier |

| MeteorCNC:4T Series Catalog | |

| MeteorCNC:4H Series DataSheet | |

| Brand | Accelus Robotics |

| Warranty | 1 Year |

| Color | Black |

| Automatic Grade | Automatic |

| Country of Origin | India |

| Warrenty | 1year |

| Type | Wood Lathe Controller |

| Condition | New |

| After-Sales Service Provided | Yes |

| No. of axis | 4 |

| Axis Name | X, Y, Z, 4th |

| Numbers of Input | 24 (Isolated NPN) |

| Numbers of Output | 12 (Isolated NPN) |

| Encoder | Differential Encoder Facility for remote MPG |

| Spindle Operation | 0-10V Analog Output or PNP multistep |

| Storage capacity | Upto 1GB |

| Product Code | MeteorCNC 4T |

| Port | Mumbai India |

| Payment Terms | T/T |

| Delivery Time | 1-2 Days |

MeteorCNC 4T series is 4 axes CNC lathe controller manufacturer with handheld running upto 500khz differential pulse & direction output for smooth operation with 24 Inputs, 12 Outputs, 1 Analog output and encoder facility available.

MeteorCNC 4T series is a 4 axes CNC lathe controller operated with handheld provides up to 500khz jitter free differential pulse & direction output for smooth motion at the motor end. It comes with 4 axis control card and handheld and inbuilt MPG available with few extra inputs and outputs with additional facility of external high speed differential encoder input which can be used for either MPG remote for jogging of axis OR spindle encoder feedback for tapping cycle.

A 4-axes CNC machine functions much like its 3-axes counterpart. With addition of one extra rotational motion from the controller makes it very special for making critical works. The workpiece is in a stationary position, and the cutting tool works on it to remove material and mold the desired part. However, as the name indicates, 4-axis machining adds an axis of rotation to the standard X, Y, and Z movement. This extra movement is rotation along the X-axis, which forms a fourth plane the A-axis OR rotational along Y-axis. The

rotation may be accomplished by moving the tool or the workpiece which is being machined, and the axis of rotation may be parallel to or perpendicular to the tool surface. The orientation of the axis of rotation determines how easy it is to machine certain features and undercuts on a given machine.

4 individual simultaneously running axis machine is majorly used in wood working / router machine industries for making statues, stone cutting/ engraving machine for pillar making etc. making the job faster and easier for the users.

Additional Information:

- Delivery Time: 1 day